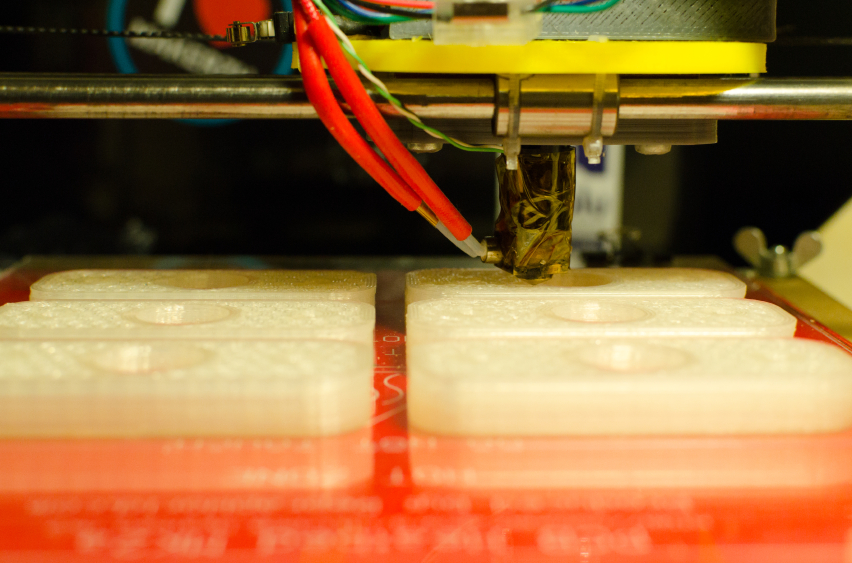

An innovative approach to 3D printing may open the door to sustainable outdoor sporting goods. Fused particle fabrication (FPF) allows an additive manufacturing system to create skateboards and snowshoes from recycled plastic.

The FPF method makes it possible to use waste plastic as feed material for a 3D printer. The resulting end products meet the special requirements of sporting goods while also drawing from sustainable sources of material.

Michigan Technological University (Michigan Tech) researchers teamed up with startup company re:3D, Inc. They came up with the Gigabot X, an open-source FPF additive manufacturing unit.

Their study tackled how FPF technology might help 3D printing hubs earn a profit while also producing environmental-friendly products. They showed it was possible to get more than 1,000 percent return on their investment for a Gigabot X unit that used recyclable feedstock and saw considerable activity.

Fabrication laboratories, makerspaces, public libraries, and schools might benefit from FPF printers.

“With well over 1,000 Fab Labs worldwide spreading fast and morphing into environmentally friendly 'green fab labs', the Gigabot X could be a useful tool to add to their services as well as other makerspaces,” explained Michigan Tech researcher Joshua Pearce. (Related: New metamaterial can silence sound.)

The new Gigabot X industrial 3D printer takes waste plastic and recycles it into new products

In an earlier trial, Gigabot X demonstrated its ability to accept various kinds of waste plastics. It turned those materials into useful products.

The new FPF device evolved from an earlier design called the "recyclebot." The ancestral system turned waste plastic into filaments for 3D printers.

To increase the efficiency of 3D printing with recycled plastic, the Michigan Tech researchers improved the way the waste material gets sorted, sifted, and grouped.

Plastic becomes weaker after going through melting and extrusion processes. It will last five such cycles before getting too weak for use.

Gigabot X resolved this problem through the FPF process. Also called fused granular fabrication (FGF), it prints directly from the shredded plastic.

By dropping the step of heating the plastic into a filament before the 3D printing process, FPF/FGF 3D printers save on a melt cycle. They preserve the mechanical strength of the recycled plastic.

The ability of Gigabot X to use any plastic material — including waste plastic — as feed-stock played a considerable part in the economics of its use. So did its size.

A single unit costs around $18,500. However, anyone who can afford the upfront investment may expect a larger potential return.

The economics of running an FPF 3D printer

For their latest study, the Michigan Tech researchers 3D printed a skateboard deck, a double-bladed kayak paddle, and snowshoes. In the case of the paddle, they produced child-sized and adult-sized units.

They printed one example of each product using different materials: Standard filaments, fresh plastic pellets, and waste plastic.

Next, they took the prices of low-end and high-end outdoor sporting goods on the commercial market. They compared those with the costs of 3D printed equivalents made from the different plastics.

Finally, they applied these costs to scenarios with varying production capacity — weekly printing, one new job daily, two new starts each day, and nonstop printing.

They reported that 3D printed kayak paddles, skateboards, and snowshoes were usually cheaper and easier to make than commercial counterparts. Further, FPF 3D printing saved even more money if it recycled waste plastic instead of using fresh plastic pellets.

“Once the capital costs are taken care of, which can often be less than a year, FPF or FGF machines have an enormous potential to make profit,” Pearce remarked. “Essentially, if you're using it more than once a week then you're making money easily.”

Sources include:

Please contact us for more information.