Imagine a city that doesn't have to rely on factories several hundreds of miles away to supply the needs of its residents. This self-sufficient city could become its own manufacturing hub. Now, researchers from Cardiff University have found a way to make that happen.

In a recent study published in the journal Computers & Operations Research, researchers described how 3D printing manufacturing hubs can optimize city logistics, or the delivery and collection of goods in urban areas.

Transforming cities via 3D printing

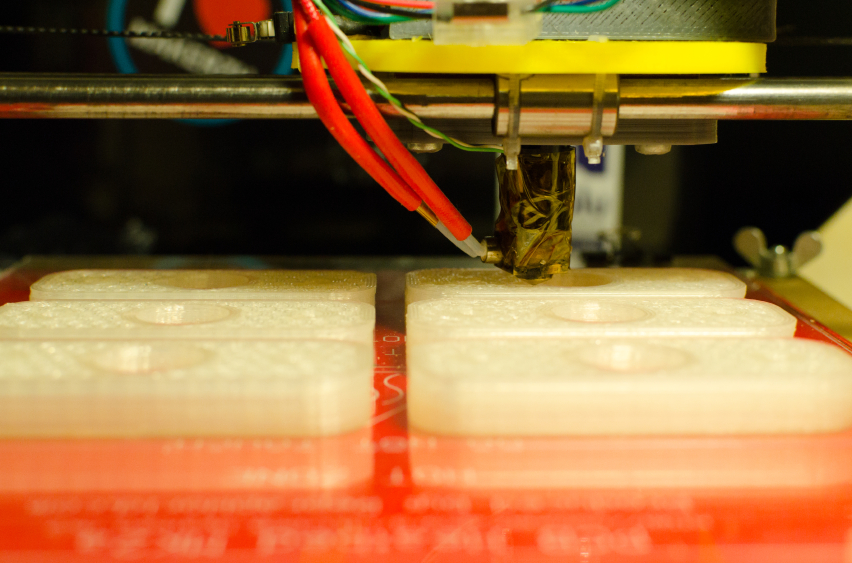

3D printing is a manufacturing process in which 3D printers lay down materials, layer by layer, to create a three-dimensional object. These printers take instructions from digital files that contain three-dimensional data.

Many firms have recently adopted 3D printing to streamline their operations. Global shipping and logistics provider UPS, for example, fitted some of its stores with 3D printers to establish an on-demand printing network for American manufacturers.

3D printing has a big potential to transform cities. In fact, it may soon replace "multi-echelon transportation systems," which have been the dominant logistics model dictating how cities obtain their residents' needs. Such a system outsources manufacturing and relies heavily on layers of suppliers spread across multiple distribution centers.

The researchers believe that 3D printing could be the technology to shake things up. For their study, they investigated how integrating 3D printing manufacturing hubs with city logistics can be applied to the distribution of hearing aids to city customers.

"Generally, production and transportation problems are solved separately," the researchers explained. "In our work, we show one possible complementary approach where local production and distribution for urgently required customized medical devices can be integrated."

After studying the transport and production of 3D printed hearing aids on a daily and weekly basis, the researchers developed an algorithm that improves the fulfillment of customer orders and ensures on-time deliveries. This algorithm is able to maintain high 3D printer usage rates and efficient van utilizations.

Using this algorithm, the researchers then created a scoreboard-based app that small and medium-sized businesses can use to optimize their production and delivery operations. The app can be easily reconfigured to make it suitable for a certain production scenario, like when there are too many orders to process. (Related: Why 3D printing is the ultimate game-changing technology for freedom, self-reliance and the spread of democracy.)

The team believes that the lockdowns and supply chain disruptions caused by the COVID-19 pandemic further underscored the relevance of localized logistics solutions.

"There is a lot of appetite from logistics service providers to implement 3D printing. And our work shows obvious commercial opportunity," the researchers said.

The many applications of 3D printing

On top of healthcare, integrating 3D printing manufacturing hubs with city logistics could also work for other delivery-based sectors, such as retail stores and supermarkets.

"We already know that supermarkets are using scheduling algorithms to decide how to deliver goods to stores or homes," the researchers noted, adding that combining 3D printing and city logistics would offer an excellent opportunity to extend a company's presence to other markets.

3D printing is currently being used for the manufacture of various products, such as houses and spare parts. New York real estate firm SQD4, for instance, made a demo house with 3D printed walls. The actual printing time for the walls took just two days while constructing the entire house took eight days. Following this successful demo, the firm put up an online listing for a soon-to-be-built home whose foundations and walls will be 3D printed.

Meanwhile, the Department of Defense will soon be 3D printing spare parts for its own equipment. The department recently hired an additive manufacturing company to create a mobile 3D printing lab that can be transported inside a shipping container. This lab will allow troops to quickly manufacture things like aircraft ducting, replacement lens caps, advanced electronics, medical equipment and more on the battlefield.

3D printing is a real game-changer that could improve lives in cities and elsewhere. Learn more about how 3D printing works and its numerous applications at Inventions.news.

Sources include:

Please contact us for more information.