A new (and quiet) era of acoustics is opening up as engineers from Boston University have created a material that can silence noise without reducing airflow. In their study, which appeared in the journal Physical Review B, researchers led by Professor Xin Zhang and doctorate student Reza Ghaffarivardavagh of Boston University's mechanical engineering department built what they called an "acoustic metamaterial." They combined math and 3D printing technology to make a structure with precise mathematical dimensions that let air and light pass through, but not sound.

Amping noise mitigation

Sound is a measure of the vibration of air molecules. When sound hits a material, three things can happen: it can be reflected (such as an indoor basketball court); transmitted (such as through a thin material); or absorbed, where the wave encounters a porous surface and gets trapped in it. This is similar to how everything sounds muffled and flat when it's snowing outside because snow absorbs sound.

A sound baffle is a construction used to absorb sound, but most are typically just thick walls. They are not an efficient use of resources, and designers normally must compromise between letting air through or keeping sound out (or containing it, in the case of theaters and indoor concerts). In fact, loud movies at movie theaters can seriously damage hearing. If loud sound sources can’t be barricaded in a conventional way (like jet engines), workers must protect their ears instead of dealing with the source itself.

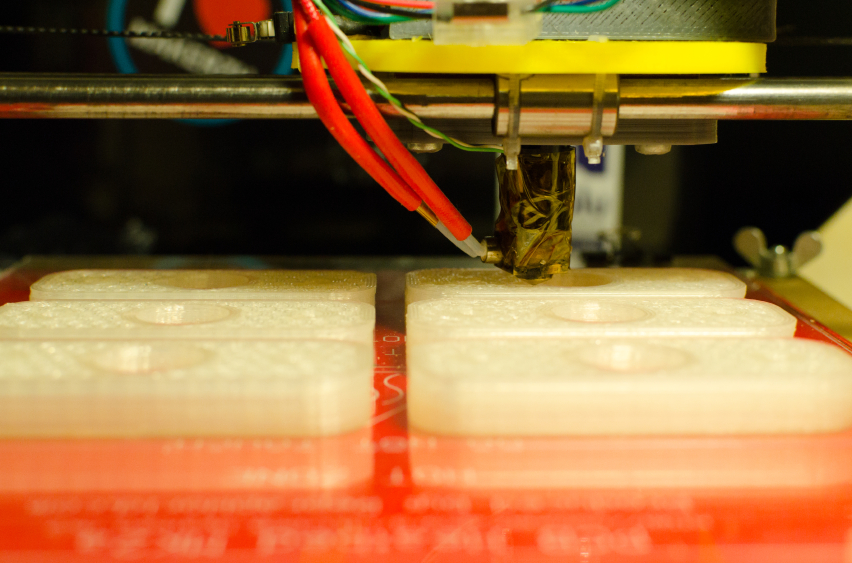

The two authors of the study used their passion for math to create a new type of sound baffle. Unlike typical acoustic materials that absorb sound, they engineered the precise dimensions of their material to instead interfere with incoming sound and send it back to where it came from. They used 3D printing to arrive at a ring-shaped device for this purpose.

With the device in hand, they inserted it into a PVC pipe attached to a loudspeaker playing music. The results were so dramatic that the study described the material as a giant mute button, which they measured to reduce up to 94 percent of sound. Without the material, the sound from the loudspeaker was almost deafening.

“The moment we first placed and removed the silencer…was literally night and day," says Jacob Nikolajczyk, one of the co-authors of the study. He adds that they have seen this effect predicted using their computer models, but it’s “…another [thing] to hear its impact yourself.”

The future is quieter

The researchers are excited to share future applications for their discovery. One of the biggest applications is muffling industrial sounds, especially in packed urban areas. It can dampen repetitive sounds and prevent hearing-related injuries in construction settings or anywhere where there’s a need for ear protection, like airports or even aircraft carrier flight decks. It can also be used to mask the noise from household appliances and tools like air conditioning units, food processors, and chainsaws.

Urban planning

This can also find applications in modern urban planning and interior design, especially one that utilizes natural lighting. Zhang and her researchers mentioned that their material is “…super lightweight, open, and beautiful,” and that as the development of the material progresses, it won’t be limited to just a donut shape. For example, each piece of the material can be fashioned into hexagons or cubes and scaled up to build a permeable wall or divider, which can be used for both ventilation and sound insulation.

Passive noise canceling

Active noise canceling or ANC also uses a similar concept in acoustics, which generates an exact waveform opposite of the external sound to cancel it out. ANC creates deeper immersion into whatever the user is listening to thanks to fewer distractions. Acoustic metamaterials may improve noise-canceling technology, including the fabrication of smaller headphones in an industry where bulk is the biggest complaint. Units using this material would also have improved battery life as they would no longer need to emit a canceling signal. The mindfulness industry, which is set to become a $2 billion business by 2022, may also benefit from these advances.

The possibilities for an acoustic metamaterial are endless, concludes the report. As noise pollution increasingly becomes a concern, stifling noise may soon prove to be a blessing.

Sources include:

Please contact us for more information.