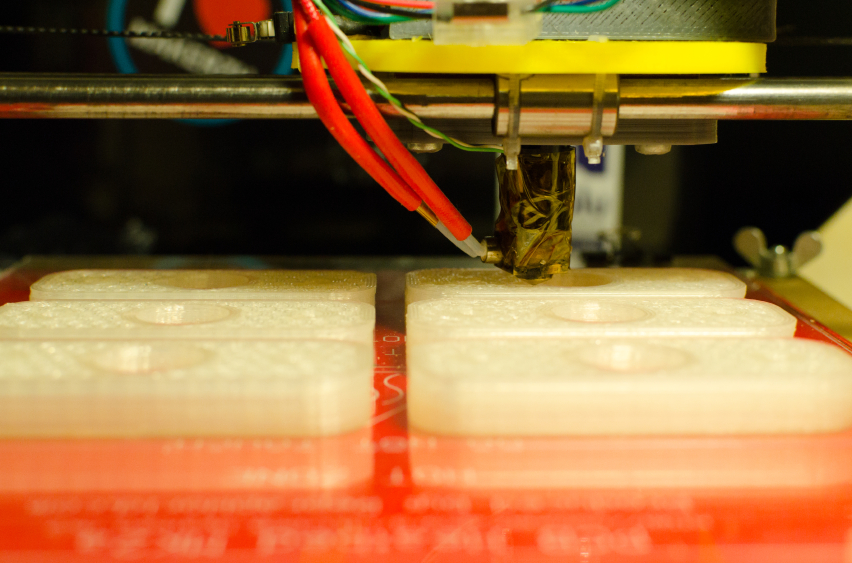

European researchers, engineers, and construction experts have teamed up to develop a new generation of green concrete. The concrete mixtures are going to be made from renewable resources, will be compatible with 3D printing techniques, and are capable of being printed on the water – or even underwater.

The mixtures are intended for 3D printing breakwater units on site at the numerous canals and ports that make up a good chunk of the transportation network in Flanders, Belgium. The research project is financially supported by Strategic Initiative Materials (SIM) Flanders and Flanders Innovation & Entrepreneurship (VLAIO).

Ghent University is in charge of figuring out the most appropriate raw materials, how to combine the ingredients into a usable concrete mixture, and refining the result. It will be supported by Netherlands-based engineering firm Witteveen+Bos.

Belgian construction company BESIX will test the new mixture in its 3D concrete printing machines. Another local company, the start-up ResourceFull, is tasked with marketing the green concrete to potential customers in Belgium.

Given the various expertise of the partners, it is hoped that the project will be able to produce new, groundbreaking, and environment-friendly concrete mixtures that can be used for hydraulic engineering construction. (Related: Could bioplastics be a more sustainable option for 3D printed buildings?)

3D printing could make it cheaper to build breakwaters

The field of 3D printing is developing very quickly. 3D printers are beginning to usurp traditional approaches to building concrete structures. However, it was only recently that the technology was considered for use in breakwaters.

A breakwater is a structure built near the coast to either manage the coastline or to shield an anchorage from weather and sediments. It is made up of numerous concrete units.

An individual breakwater unit is fairly cheap to make. Most of the construction cost comes from the logistics required to haul all of the units from the production yard to the site.

Since the concrete units are both bulky and heavy, they can only be transported over ground via large trucks. These vehicles are not only expensive to acquire or hire, but also use up a lot of fuel. Running a fleet of trucks would break most budgets.

Additive manufacturing systems offered the possibility of printing breakwater units on site. With the right printer and mixture, the unit could even be printed underwater.

Furthermore, 3D printing could also allow construction companies to design a breakwater unit specifically for local conditions. The printer could make complicated shapes that are optimized for the sea currents and wave patterns. It could also print a layered surface that increased the amount of energy dissipated by the unit.

Making a green concrete that can be 3D printed into breakwater units

However, the sheer size of a breakwater unit makes it a challenge for 3D printing. The current generation of printable concrete mixtures have high binder contents, making them vulnerable to thermal cracking. Furthermore, printed structures are also prone to cracking when they dry up and shrink.

The research partners plan to develop a printable concrete mixture that can withstand a marine environment. The minimum requirement is to print the contour of the breakwater unit. If all goes well, the green concrete will also be able to print the infill pattern.

Furthermore, the researchers are considering the environmental impact of the concrete mixture. If only the contour of the breakwater unit gets printed, it will need a filling material that is also made from sustainable resources. They will also improve the interlayer, which would further increase the sturdiness of the unit.

Once the mixture is ready, it will be used to 3D print scale model breakwater units. The models will be tested for durability and performance.

Sources include:

Please contact us for more information.