Advertisement

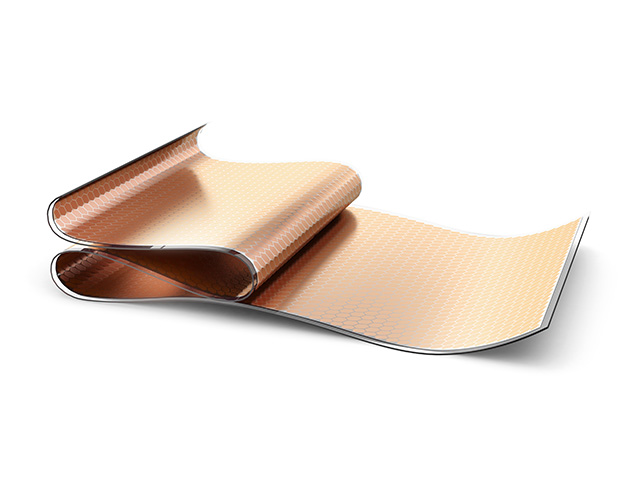

In a few year’s time, you could be wearing an efficient solar cell on your clothes that is just as thin, light, and flexible as a T-shirt design. In a report from The Mainichi, a Japanese research team recent showcased a new ultra-thin organic photovoltaic (OPV) cell that can be heat-printed onto fabric.

The new design is made from organic materials. Despite measuring just three micrometers in thickness, it is also very tough thanks to the microstructures formed by the production process. The solar cell can stretch and fold alongside the fabric it is affixed to without cracking.

In addition, the OPV can maintain 80 percent efficiency even at temperatures of up to 212 degrees Fahrenheit (100 degrees Celsius). It can therefore be applied via the hot-melt process used by the apparel industry.

With an energy conversion efficiency of 10 percent, the new cell is superior to previous ultra-thin organic designs. It is the outcome of a joint effort between the Riken Research Institute (Riken) and Toray Industries Inc.

The researchers published the findings of their study in the online version of the Proceedings of the National Academy of Sciences. (Related: The solar energy industry is exploding with new technologies, including “solar paint”.)

Ultra-thin solar cells can provide off-grid electricity in homes, wilderness, and disaster areas

The ultra-thin solar cells could be used to power handheld devices and wearable electronics. An adapter needs to be plugged into an external power source and batteries are bulky and heavy, while a photovoltaic cell only needs a source of steady sunlight.

The OPV cells could also be glued onto the tough fabric that comprise tents. This would reduce or even remove the need to bring noisy generators and flammable fuel supplies.

Tents equipped with flexible solar cells will enjoy access to electricity even when the grid is far away, such as in the wilderness during camping trips. The same convenience applies during natural disasters like earthquakes and storms that bring down the electrical grid.

In addition, flexible solar cells would be much easier to set up, take down, and put into storage than conventional solar panels. The latter need to be assembled, while the tent-mounted cells can be folded alongside the tent itself.

Riken research Takao Someya remarked that organic solar cells are much cheaper and easier to manufacture than conventional equivalents. Furthermore, OPV technology is sure to be in high demand.

The rapidly increasing number of Internet of Things (IoT) and wearable electronic devices require direct sources of power. If the source of power is flexible enough to be fastened on curved or rough surfaces, they could be integrated onto many more items.

Organic solar cell technology may enter service by 2020s

Someya said he and his teammates are still refining the new technology. The organic solar cells are still prone to breaking down when they come into contact with oxygen or get drenched by water.

While the cell uses double-layer barriers for maximum protection, the ultra-thin material cannot keep out all the environmental influences, such as heat or moisture. Any thicker and the overall lifetime of the device will be affected.

Still, testing has shown that the prototypes can last up to 500 hours of continuous operation while exposed to air and more than 2,000 hours in storage. The cells have also managed to maintain a good power conversion efficiency despite being subjected to temperatures that would boil water.

Once the durability and water resistance issues have been worked out, the new solar cells will be ready for true production. Both Riken and Toray Industries plan to start rolling them out during the early half of the 2020s.

Read more articles about other examples of wearable, flexible solar cells at Power.news.

Sources include:

Submit a correction >>

This article may contain statements that reflect the opinion of the author

Advertisement

Advertisements