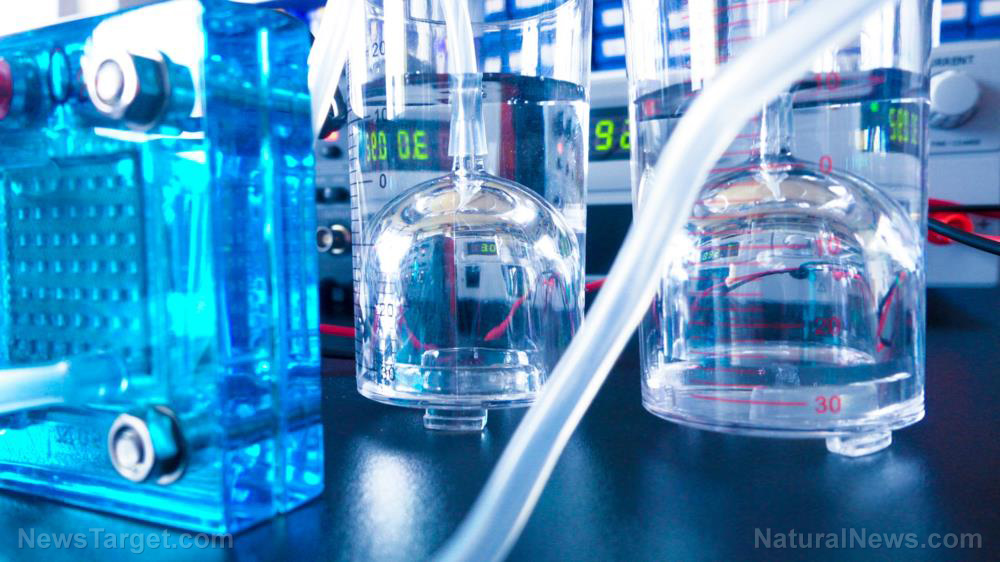

Researchers at RMIT University in Australia have come up with a new way to make hydrogen fuel directly from seawater without the need for desalination.

The team skipped the need for desalination and its associated cost by splitting seawater directly into hydrogen and oxygen. Their method conserves energy while minimizing carbon emissions, which is a win-win situation.

For many years, hydrogen has been touted as a viable, clean fuel for future use in many applications. Especially for industries that are much more difficult to "decarbonize," including manufacturing, aviation, and shipping, hydrogen fuel could be a real solution.

"Almost all the world's hydrogen currently comes from fossil fuels and its production is responsible for around 830 million tonnes of carbon dioxide a year*, equivalent to the annual emissions of the United Kingdom and Indonesia combined," reads a report on the new study.

"But emissions-free 'green' hydrogen, made by splitting water, is so expensive that it is largely commercially unviable and accounts for just 1% of total hydrogen production globally."

(Related: Check out our earlier coverage about how clean hydrogen fuel has the potential to revolutionize the clean energy economy.)

RMIT's hydrogen production method produces no toxic chlorine byproducts

Lead researcher Dr. Nasir Mahmood, a vice chancellor senior research fellow at RMIT, says traditional "green" hydrogen fuel production methods are costly and often rely on freshly desalinated water. The process is both expensive and time consuming, which is a deterrent for industry.

We are building the infrastructure of human freedom and empowering people to be informed, healthy and aware. Explore our decentralized, peer-to-peer, uncensorable Brighteon.io free speech platform here. Learn about our free, downloadable generative AI tools at Brighteon.AI. Every purchase at HealthRangerStore.com helps fund our efforts to build and share more tools for empowering humanity with knowledge and abundance.

"We know hydrogen has immense potential as a clean energy source, particularly for the many industries that can’t easily switch over to be powered by renewables," Mahmood is quoted as saying.

"But to be truly sustainable, the hydrogen we use must be 100% carbon-free across the entire production life cycle and must not cut into the world's precious freshwater reserves."

Mahmood would go on in a statement to explain how his team's method of creating hydrogen fuel straight from seawater is both scalable and far more cost-effective than any other green hydrogen approach currently in the market.

"With further development, we hope this could advance the establishment of a thriving green hydrogen industry in Australia," he added.

The lab-scale study, which was published in the Wiley journal Small, explains that a provisional patent application was recently filed for the new method.

According to an announcement, what makes this new process unique is that it does not produce any chlorine as a byproduct – meaning no possibility for chlorine pollution and the potential creation of dioxins from the incineration of that chlorine pollution.

"The biggest hurdle with using seawater is the chlorine, which can be produced as a by-product," Mahmood said.

"If we were to meet the world's hydrogen needs without solving this issue first, we'd produce 240 million tons per year of chlorine each year – which is three to four times what the world needs in chlorine. There's no point replacing hydrogen made by fossil fuels with hydrogen production that could be damaging our environment in a different way."

"Our process not only omits carbon dioxide, but also has no chlorine production."

Instead of using traditional electrolyzers to split water into hydrogen and CO2, the Mahmood team's method uses a special catalyst that requires minimal energy to run and works at room temperature.

Most other seawater splitting methods are complex and difficult to scale, but not this one.

"Our approach focused on changing the internal chemistry of the catalysts through a simple method, which makes them relatively easy to produce at large-scale so they can be readily synthesized at industrial scales," said PhD candidate Suraj Loomba.

More related news can be found at EnergySupply.news.

Sources for this article include:

Please contact us for more information.