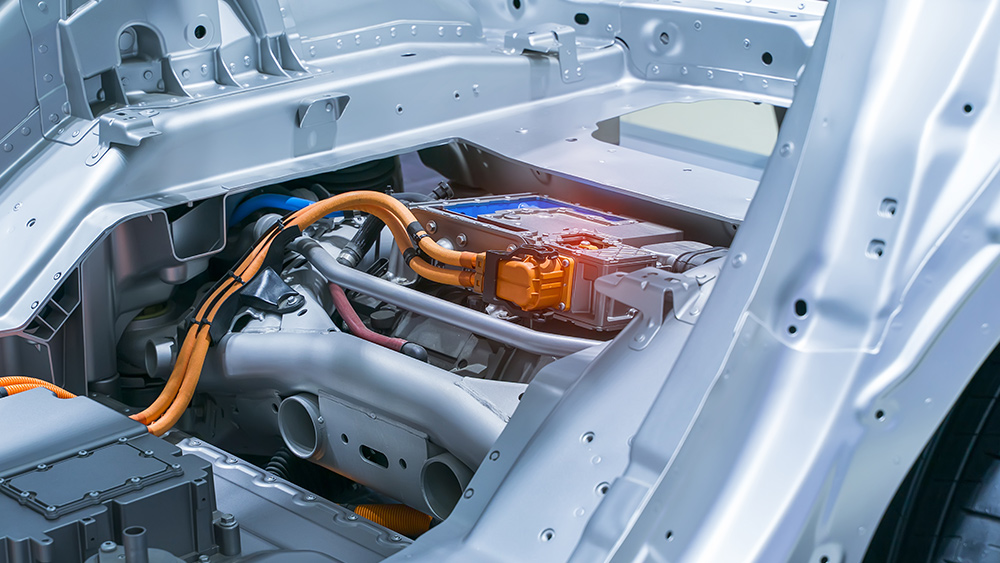

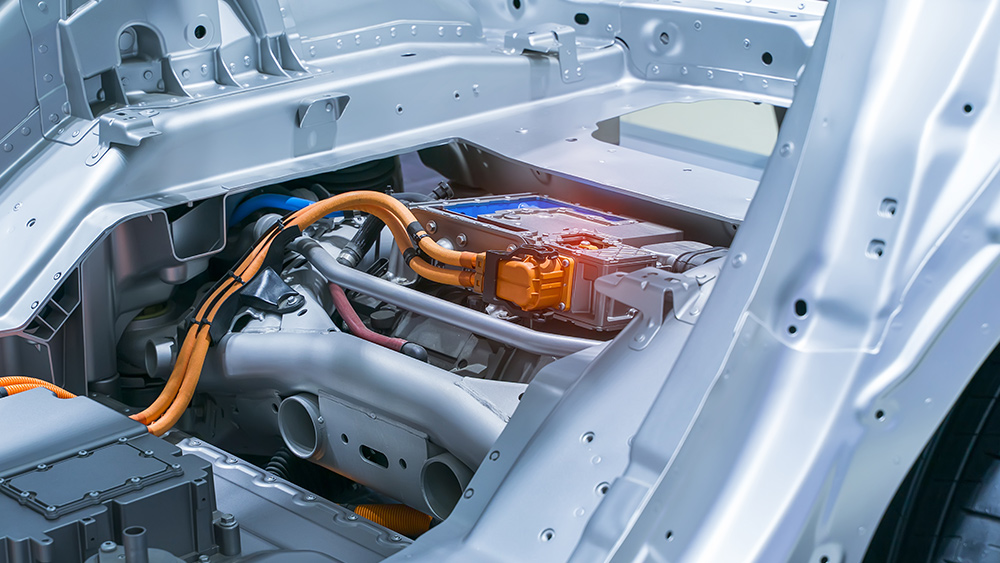

A recent study has figured out how valuable materials in old electric vehicle (EV) batteries can be "harvested" and used to make new batteries.

The disposal of old batteries remains a significant challenge for EVs. Once these batteries reach the end of their service lives, they are dumped as electronic waste or e-waste.

E-waste, which includes old computers, smartphones and other equipment, is already a massive worldwide problem. As such, EV industry analysts say that similar difficulties could develop as more EV batteries reach the end of their lives.

With this in mind, researchers from the University of Birmingham in the U.K. looked into how the still valuable metals and materials inside these batteries, such as cobalt, could be extracted for use in new batteries.

Dead batteries could become source for all important cobalt

In their study, published in the journal Nature, the researchers posited that dead batteries from older EVs could be a valuable secondary source for many critical materials needed in battery production.

"In the future, electric vehicles may prove to be a valuable secondary resource for critical materials, and it has been argued that high cobalt-content batteries should be recycled immediately to bolster cobalt supplies," the study states.

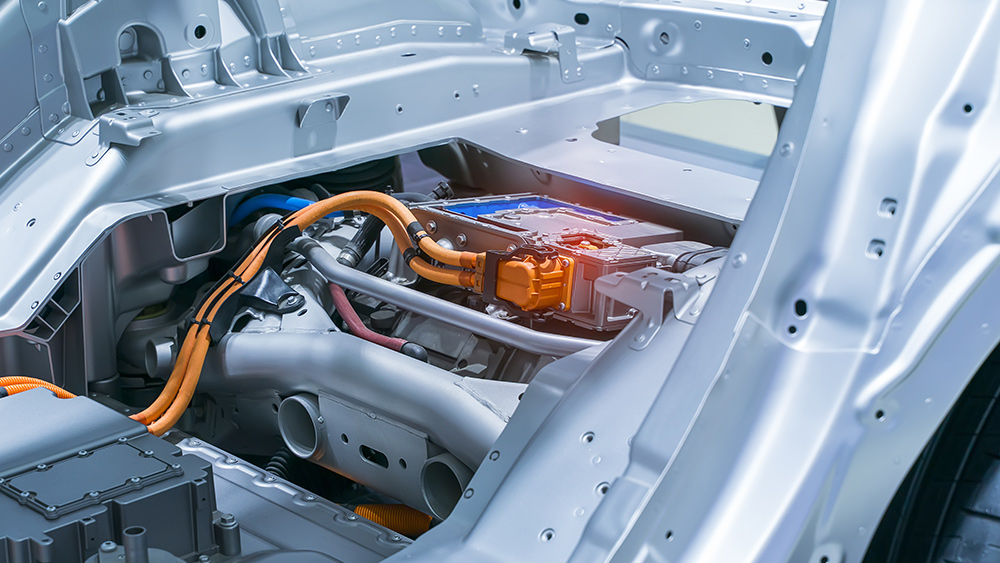

The researchers explained how recycling metals from dead batteries could help make EV manufacture more sustainable in the future.

"If tens of millions of electric vehicles are to be produced annually, careful husbandry of the resources consumed by electric-vehicle battery manufacturing will surely be essential to ensure the sustainability of the automotive industry of the future," they write.

While cobalt is a byproduct of the production of other metals, a large part of the world's supply – around 60 percent – comes from mines in the Democratic Republic of Congo.

This has been seen as problematic. For one, cobalt mining in the DRC has been linked to unsafe and unethical labor practices. In addition, the majority of the mining operations are controlled by a handful of companies, predominantly Chinese ones. The latter control an estimated 40 percent of all the extracted cobalt from the country.

As such, there has been a push by automakers to develop EV batteries that don't use cobalt.

But with their study, the researchers have put forward a new source of cobalt for batteries. This can allow EV battery manufacturers to use their existing battery technology without having to tie themselves to international sources of cobalt that have political complications.

EV battery recycling still complicated and costly

Even as scientists look at ways to harvest precious metals from old EV batteries, recycling them is still a complicated endeavor.

EV batteries as they're made today "are really not designed to be recycled," according to Dana Thompson, a materials scientist at the University of Leicester in the U.K. She explains further that cutting too deep into an EV battery, or in the wrong place, can lead to a short circuit that can cause a fire. It can also release toxic fumes into the environment.

What's more, EV batteries differ widely in chemistry and construction depending on the manufacturer. This makes it difficult to make efficient recycling systems. Meanwhile, the tough glues that bond the parts of EV batteries together make them difficult to tear apart. (Related: Bacteria can recover precious metals from old batteries for use in new ones.)

Put together, these challenges have meant that it's often cheaper for battery makers to buy freshly mined metals than to use recycled materials.

Now, the government is stepping in to encourage the development and use of recyclable batteries. The Department of Energy (DOE) has already pumped some $15 million to coordinate studies by scientists in academia, industry and government labs toward recyclable EV battery development.

According to Linda Gaines, who works on battery recycling at the DOE’s Argonne National Laboratory, the need for progress on EV battery recycling has become urgent as the industry continues to grow.

"The sooner we can get everything moving, the better."

Follow NewEnergyReport.com for more on EV batteries and efforts to recycle them.

Sources include:

Please contact us for more information.