When it comes to energy storage technology, researchers are either trying to perfect alternative types of batteries or tweaking the performance of lithium-ion batteries to the absolute limits. One of the latest efforts comes from a New York-based team, who has come up with a new way to extend the life of lithium cells while also ensuring its safety.

The researchers applied an incredibly thin layer of boron nitride to the solid electrolytes in lithium metal batteries. The nano-coating increased the stability of the volatile metal.

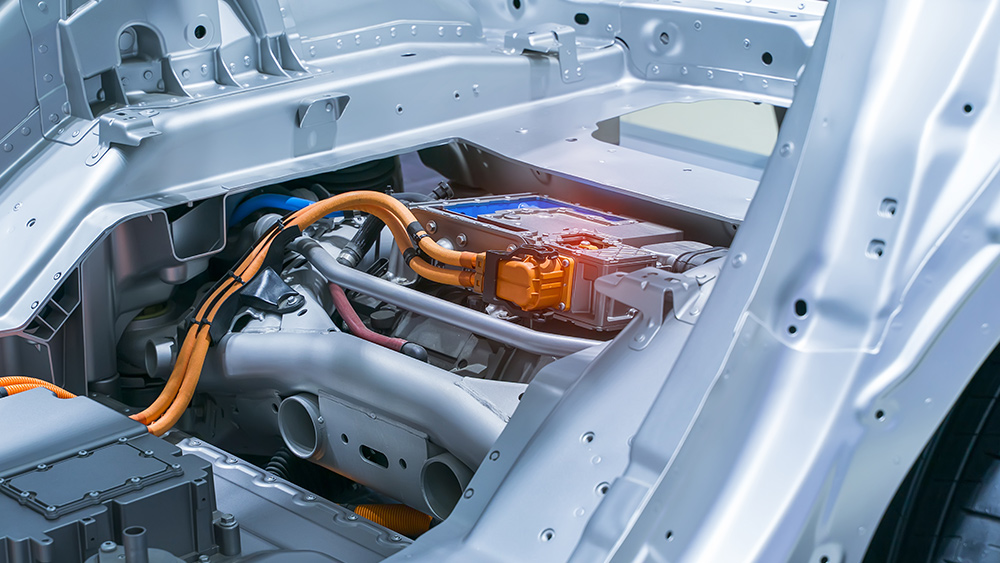

The typical lithium-ion battery suffers from drawbacks. For one, its low energy density imposes a short lifespan on the cell. At the same time, the liquid that serves as its electrolytes is prone to short circuits and catching fire.

To solve the issue of energy density, researchers replace the graphite anode in a lithium-ion battery with one made of lithium metal. The substitute material theoretically delivers several times the electric charge of graphite.

Unfortunately, the lithium plating process tends to produce dendrites. If a dendrite pierces the membrane that divides the battery, it may trigger a short circuit and electric fire. (Related: Engineers develop high energy density all-solid-state batteries.)

A way to use solid electrolytes and lithium metal anodes together

“We decided to focus on solid, ceramic electrolytes,” explained Columbia University researcher Yuan Yang. “They show great promise in improving both safety and energy density, as compared with conventional, flammable electrolytes in Li-ion batteries.”

Yang's team sought to improve rechargeable solid-state lithium batteries, which may become the next-generation energy storage systems.

Ceramics are non-flammable. Most solid electrolytes use them as materials to ensure their safety. Furthermore, solid ceramic electrolytes have the mechanical strength to inhibit lithium dendrites. They enable the use of lithium metal as a coating for the anodes of a battery.

However, lithium metal corrodes most solid electrolytes. Their instability prevents the electrolytes from seeing use in batteries.

Columbia researcher and lead study author Qian Cheng explained that they depended on lithium metal to boost the energy density of a battery. They needed a way to modify solid electrolytes that allowed the use of lithium metal for the anode.

Cheng and Yang looked for a material that might stop the lithium anode from destabilizing the solid electrolytes. Such an interface must have stability, high insulation against electrons, and high ionic conduction to efficiently transport lithium ions.

Finally, the material must maintain the energy density of the battery. It needed to be incredibly thin.

Developing a "bulletproof vest" for solid electrolytes against lithium metal

The Columbia researchers applied a nano-thin layer of boron nitride on the ionic conductor that served as the solid electrolyte. The nano-film barred contact between the electrolyte and the lithium metal anode.

They also added a trace amount of polymer. This liquid electrolyte seeped through the interface of the electrode and solid electrolyte.

The team found that boron nitride remains stable in the presence of lithium metal. When used as a protective layer, it insulates against electrons. The boron nitride layer has intrinsic defects that permits the movement of lithium ions. Further, the material is easy to prepare and apply in varying quantities.

“While earlier studies used polymeric protection layers as thick as 200 mcm, our BN protective film, at only 5~10 nm thick, is record-thin -- at the limit of such protection layers -- without lowering the energy density of batteries,” explained Cheng. “It's the perfect material to function as a barrier that prevents the invasion of lithium metal to solid electrolyte.”

He described the boron nitride layer as a bulletproof vest that stopped lithium metal. By protecting solid electrolytes, the nano-coating increased the cycling lifetime of lithium metal batteries.

Visit Nanotechnology.news for more studies and stories on the latest nanomaterial-based improvements on batteries and other devices.

Sources include:

Please contact us for more information.