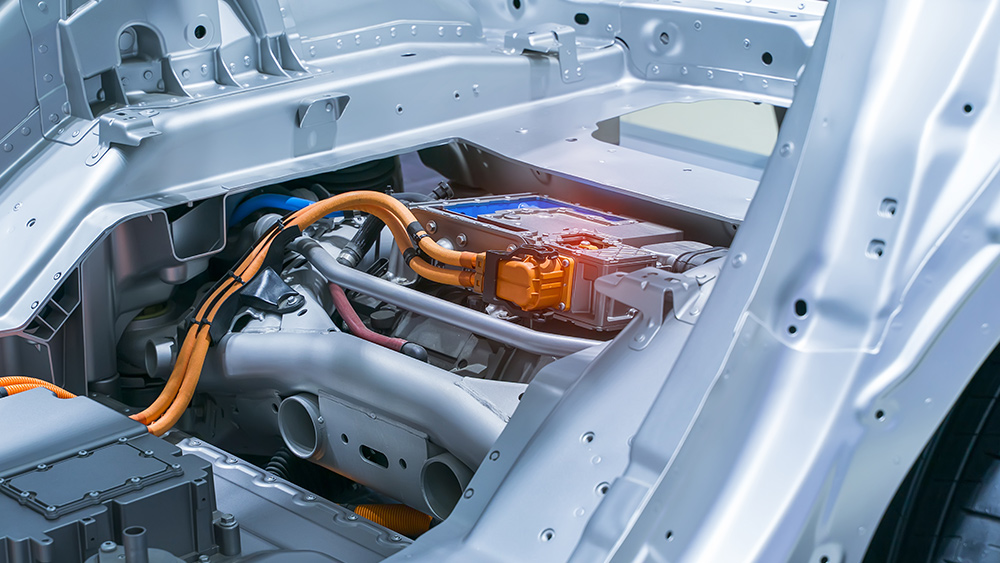

A joint effort between American and Chinese researchers have delivered a new take on the cathode of a lithium battery. Their prototype negatively-charged electrode will help reduce the size and weight of energy storage systems.

A smaller, lighter lithium battery makes it possible to fit more cells aboard electric vehicles, extending their range and endurance. It also extends the operating time of smartphones, mobile devices, and other portable electronics that run on battery power.

In the study, which was supported by the Massachusetts Institute of Technology, the researchers developed a hybrid cathode that borrows from two separate techniques of increasing energy density.

The gravimetric approach boosts the amount stored and released by each pound of battery. Meanwhile, the volumetric method improves the performance of every liter of energy storage material.

By combining the gravimetric and volumetric approaches, the researchers created a battery that possessed the strengths of both energy density-boosting techniques. Further, the synergy provided additional useful effects.

Transition metal oxides serve as the materials for the cathodes of most current lithium-ion batteries. Due to the considerable mass of the oxide-based cathode, some cells switch to sulfur-based cathodes to save weight. (Related: Engineers develop high energy density all-solid-state batteries.)

A hybrid with the strengths of two different types of cathode

There are two ways to make a cathode for a lithium battery. The intercalation method uses lithium cobalt oxide in the negatively charged electrode.

Intercalation-type cathodes deliver volumetric energy density. They maintain the crystal-like shape of their internal lattice despite the constant addition and removal of lithium atoms.

Meanwhile, the conversion type cathode swaps out the oxide for sulfur. The alternative material changes its structure to accommodate or release lithium ions. It may even melt in the electrolyte.

“Theoretically, these [batteries] have very good gravimetric energy density,” explained MIT researcher Ju Li. “But the volumetric density is low.”

Sulfur-based conversion cathodes need more materials, such as additional electrolytes and carbon (which may be acquired from recycled plastic bags).

The MIT-led research team found a way to combine the gravimetric and volumetric approaches. They built their hybrid cathode out of pure sulfur and Chevrel-phase, a sulfide compound that combines sulfur with the transition metal molybdenum.

To produce the solid cathode, the researchers squeezed together particles of both sulfur and Chevrel-phase. The resulting material conducts electricity quite well, so it doesn't need as much carbon as a pure sulfur cathode.

In turn, decreasing the number of materials also reduced the total volume of the electrode.

New sulfur-molybdenum sulfide cathode will boost energy densities of lithium batteries

The energy densities of a typical lithium-ion battery amount to 250 watt-hours per kilogram (w-h/kg) and 700 watt-hours per liter (w-h/L). If it has a pure sulfur cathode, its gravimetric energy density increases by 400 w-h/kg. However, its volumetric equivalent drops to 400 w-h/L.

In comparison, a battery with the prototype sulfur-molybdenum sulfide cathode reached more than 360 w-h/kg and 581 w-h/L. It delivered the best of both types.

Li believed that his team could raise the battery's performance to 400 watt-hours/kg and 700 watt-hours/L. A hybrid cell would match the volumetric energy density of a commercial lithium-ion battery while exceeding the latter's gravimetric energy density.

Further, they skipped the usual approach of testing the hybrid cathode on coin cells with small energy capacities. They went straight to the three-layer pouch cell that made up the lithium-ion batteries in electric vehicles and other electronic products.

The main drawback of the new battery is its shorter lifespan. It can go through the charging-discharge cycle fewer times than a lithium-ion cell.

The MIT researchers added that the problem lay with the battery's general design. Their sulfur-molybdenum sulfide cathode, however, was ready for use and would only get better with further optimization.

Sources include:

Please contact us for more information.