In a case of fighting fire with fire, Missouri-based researchers used a type of bacteria to produce the active material for making the membrane of a water filter. When exposed to light, the material released heat that killed harmful bacteria, thereby preventing the biological fouling of the filter.

In response to the increasing strain on the world's supply of safe drinking water, the National Academy of Engineering called on researchers to come up with new ways of ensuring access to clean drinking water. These methods could head off predictions that up to half of the population around the globe would find themselves living in areas with limited or no supplies of water by 2025.

Researchers at the Washington University in St. Louis created a new material that could be used in the filters of water purification systems. The material could potentially prevent dangerous microorganisms from accumulating on the membrane of the filter.

Preventing such "biofouling" from taking place would ensure the steady flow of water through the filter. The efficiency of the water filtration system would be increased, allowing for more water to be purified before the filter eventually needed cleaning or replacement. (Related: How to make your own homemade water filter.)

Combining bacterial cellulose with graphene oxide nanoparticles

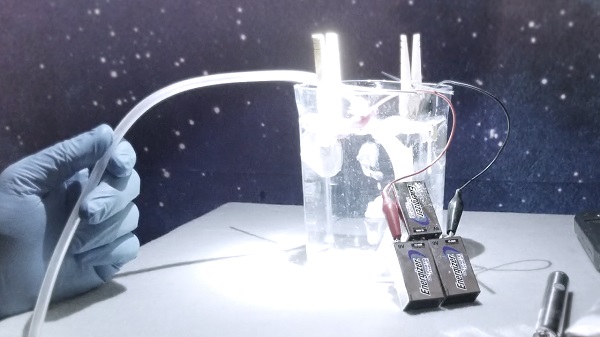

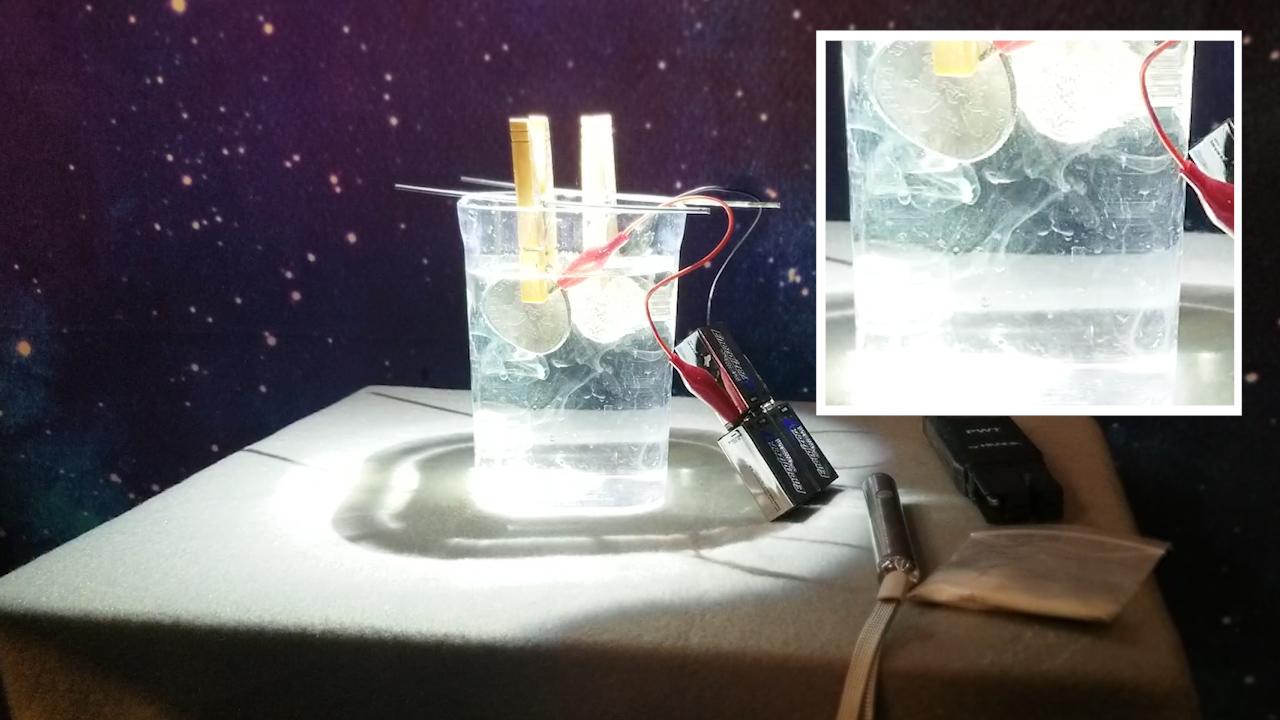

The research team employed a strain of bacteria to produce their new ultrafiltration membrane. They combined bacterial nanocellulose with graphene oxide, and the resulting material was reported to be efficient, enduring, and eco-friendly.

Biofouling is a very common problem in water filtration systems. Almost half of all cases of membrane fouling is caused by the buildup of bacteria and other microorganisms.

Lead researchers Srikanth Singamaneni and Young-Shin Jun have been working on this problem for years now. Their earlier efforts included membranes made from gold nanostars, which are very expensive to make.

Their new study sought out cheaper and sustainable materials for making water filter membranes. With that in mind, they cultured Gluconacetobacter hansenii, bacteria that turn sugars into cellulose nanofibers.

During the growth phase of the bacteria, the researchers added graphene oxide flakes to the nanocellulose. The graphene oxide became trapped inside the bacterial membrane, thereby increasing the durability and stability of the cellulose.

Next, the bacteria were killed with a base solution. The process also eliminated the oxygen groups of graphene oxide, converting it into reduced graphene oxide.

An antibacterial membrane made by a different bacteria

Tests showed that exposure to sunlight triggered the reduced graphene oxide to start producing heat. This caused the water in contact with the membrane to get hotter, which killed harmful bacteria.

"If you want to purify water with microorganisms in it, the reduced graphene oxide in the membrane can absorb the sunlight, heat the membrane and kill the bacteria," explained Singamaneni in their paper published in the journal Environmental Science & Technology.

He, Jun, and their colleagues tested the effectiveness of the bacteria-killing membrane by exposing it to E. coli bacteria before shining sunlight on it. They found that three minutes of exposure to sunlight sufficed to kill the E. coli bacteria by heating the water to more than 158 F (70 C), the minimum temperature needed to kill the bacteria.

The researchers believed that their new bacteria-killing membrane could be implemented as a module in reverse osmosis water filtration systems. The membrane would be fitted with either LEDs or a nanogenerator that converted the flow of the water into light and heat. If this new approach could be scaled up to an industrial level, it could see use in developing countries that have limited supplies of clean water.

Sources include:

Please contact us for more information.