Advertisement

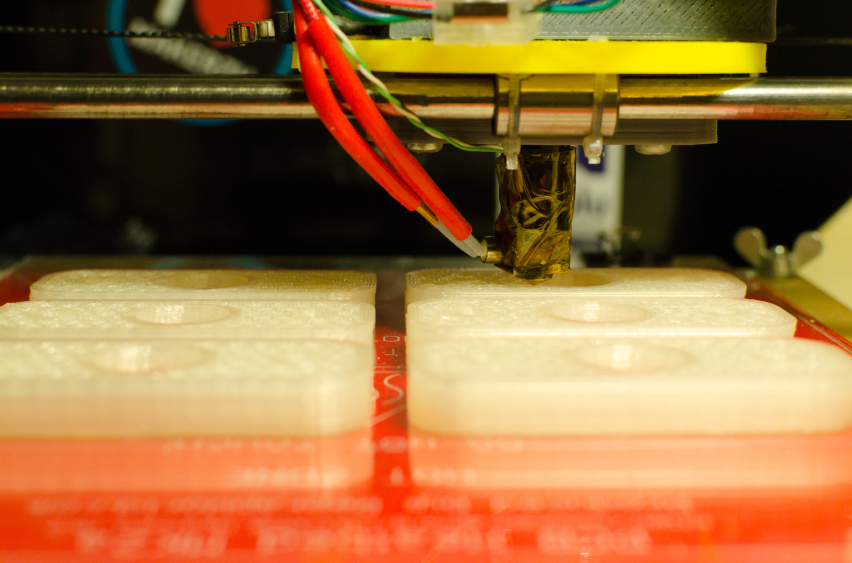

A newly developed biomaterial is not just capable of being accepted by the body, but is also usable by 3D printers. Its Swiss creators demonstrated how the biocompatible hydrogel can be used to print artificial ears and other biomedical implants.

The hydrogel is comprised of several biopolymers, including tiny crystals made from plant cellulose. When it is heated into a viscous state by a 3D printer, the material can be shaped into complicated three-dimensional structures.

These printed structures are soft and pliable like real skin and flesh. However, they are also very stable due to the cross-linking between the biopolymers that make up the hydrogel.

Swiss Federal Laboratories for Materials Science and Technology (EMPA) researcher Michael Hausmann and his teammates are examining the unique properties of the nanocellulose composite hydrogels. They are poring over X-ray images of the printed products to determine the distribution and arrangement of the cellulose nanocrystals throughout the entire structure.

The researchers believe that the stability of their new biomaterial can be improved even further. They are also planning to increase its efficiency as a 3D printing material. (Related: New flexible sensor can map blood-oxygen levels over large areas of skin.)

New plant-based hydrogel could be used to print ear implants, artificial cartilage tissue

As the primary author of the study’s scientific paper, Hausmann said that future iterations of the hydrogel will incorporate both living cells and therapeutic materials in addition to the base materials. Only then can the material be used to manufacture true biomedical implants.

Currently, his team is trying to integrate chondrocytes into a scaffold formed by the cellulose and biopolymer. Chondrocytes are cartilage cells; getting these living cells to colonize the hydrogel scaffold will turn the structure into artificial cartilage tissue that will be accepted by the body.

The auricle or external ear is made of cartilage. Its growth and development during childhood can be affected by genetic problems. One such inheritable condition is microtia, where the external ear does not fully develop and can cause severe hearing problems.

The EMPA researchers believe that their nanocellulose-based hydrogel can be used to create implants for people with malformed ears. When combined with living cartilage cells, the 3D printed ear implants will not just reconstruct the appearance and hearing, but will also restore the lost hearing capacity.

Another potential use for the cellulose nanocrystal-based hydrogel is to replace articular cartilage in the knee and other joints. This will be welcome news for people who suffer from chronic arthritis and other conditions that wear out joint cartilage faster than normal.

This nanocellulose material is biocompatible, versatile, and sustainable

Following successful implantation, the biodegradable polymer in the artificial tissue will eventually break down. The cellulose is much sturdier, but because it is biocompatible, its persistent presence is not going to cause adverse reactions like allergies or inflammation.

“It is also the mechanical performance of cellulose nanocrystals that make them such promising candidates because the tiny but highly stable fibers can extremely well reinforce the produced implant,” Hausmann said of the cellulose nanocrystals.

A second advantage to using nanocellulose is that its hydrogel can accommodate therapeutic agents that can improve its performance as a biomedical implant. The agents can modify the shape, the properties, and the behavior of the nanocellulose, resulting in a much more effective artificial tissue.

“For instance, we can incorporate active substances that promote the growth of chondrocytes or that sooth joint inflammation into the hydrogel,” Hausmann said.

Finally, cellulose is not only a natural polymer, but the most plentiful such polymer on the planet. There will always be sufficient supplies of its raw material for use in mending damaged human tissue.

Sources include:

Submit a correction >>

This article may contain statements that reflect the opinion of the author

Advertisement

Advertisements