As countries make the transition to cleaner energy, their national transmission grids must be expanded and upgraded to handle the increased demand. German researchers are looking into the possibility of replacing standard power cables with much more efficient superconductor equivalents in short grid sections, an article in Alpha Galileo reported.

Germany is currently implementing its Energiewende ("energy transition") program. This federal program aims to create a modernized power grid that is economically, socially, and technologically reasonable.

A research team from the Karlsruhe Institute of Technology (KIT) is working with grid operator TenneT. They are testing new superconductor cables that are designed to be efficient and powerful. If the new superconductor design turns out to be a success, the power transmission lines in the three-phase grid can be built to more compact dimensions.

The total length of the German transmission grid is around 35,000 km. The federal government intends to extend this grid by an additional 5,300 km. The new lines will ensure that electricity from renewable energy sources can reach any place that needs power.

The framework calls for the use of underground power cables near cities and villages. Experts believe that partial replacement of the older cable types with new superconducting systems would increase the efficiency of the grid. (Related: Hawaii is leading other states in generating renewable energy.)

Superconductors have high loads, take up less space, and improves magnetic shielding

To this end, KIT and TenneT studied the feasibility of the specific cable and cooling concepts developed for the German transmission grid, which uses a voltage of 380 kilovolts (kV). Their study will also tackle ecological and economic concerns.

“This is a big technical challenge, because superconductor technology has never been used before on this voltage level,” explained KIT professor Mathias Noe, the coordinator for the Kopernikus ENSURE project. “We have now demonstrated that this is technically feasible with our new cable concepts.”

The KIT-designed superconductor cable can handle 2,300 megawatts (MW) of continuous power load. This high current load is excellent for an underground system; energy losses are much lower when compared to an above-ground line or a copper-based conductor cable.

TenneT project manager Hanno Stagge added that superconductor technology could also prove useful when it comes to building transmission lines. A conventional cable system that uses copper calls for the use of 12 three-phase power cables.

A superconductor-based system will only need half that number of cables to transmit an equivalent power load. Grid operators could therefore build much thinner power lines using superconducting materials.

Furthermore, the setup of the superconductor cable compensates the flow of the current in the electrical shield layer. The magnetic field does not protrude outside of the cable, allowing for electromagnetic emission-free transmission of energy.

High-temperature ceramic superconductors can work in hotter conditions

The KIT-TenneT team added that the superconductor cable technology has not yet been perfected. They also needed to improve the lead time required to cool the cable for efficient operations.

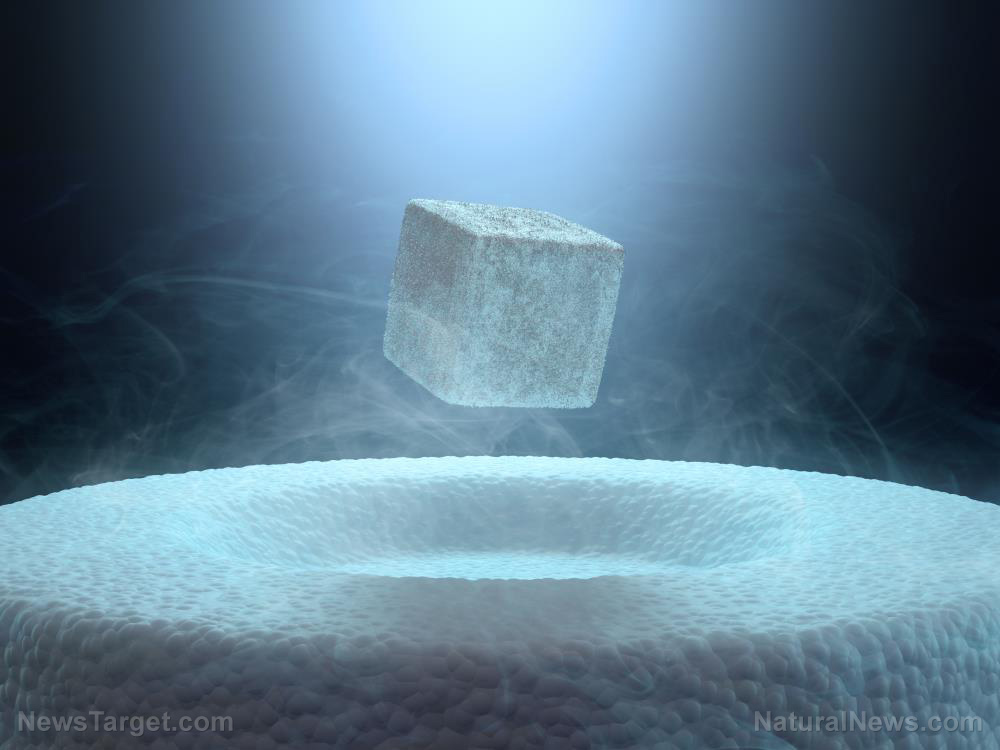

Superconductors work best when their temperature drops beneath a certain level. Once they go below this transition temperature, their electrical resistance disappears, allowing them to conduct electrical currents with almost no energy loss.

Most superconductors need transition temperatures below 23 kelvin (-418.27 degrees Fahrenheit). However, the KIT cable design uses high-temperature ceramic superconductors that will work in temperatures as high as 77 kelvin (-321.07 degrees F).

These cables will need much less liquid nitrogen coolant, resulting in lower operational costs.

“After the study, the cable, including the necessary coupling sleeves and terminations, will have to be produced first," Stagge said. "Then, it will have to be tested extensively together with a cooling system."

If you are curious about the newest technologies that improve the electrical grid, visit Power.news.

Sources include:

Please contact us for more information.