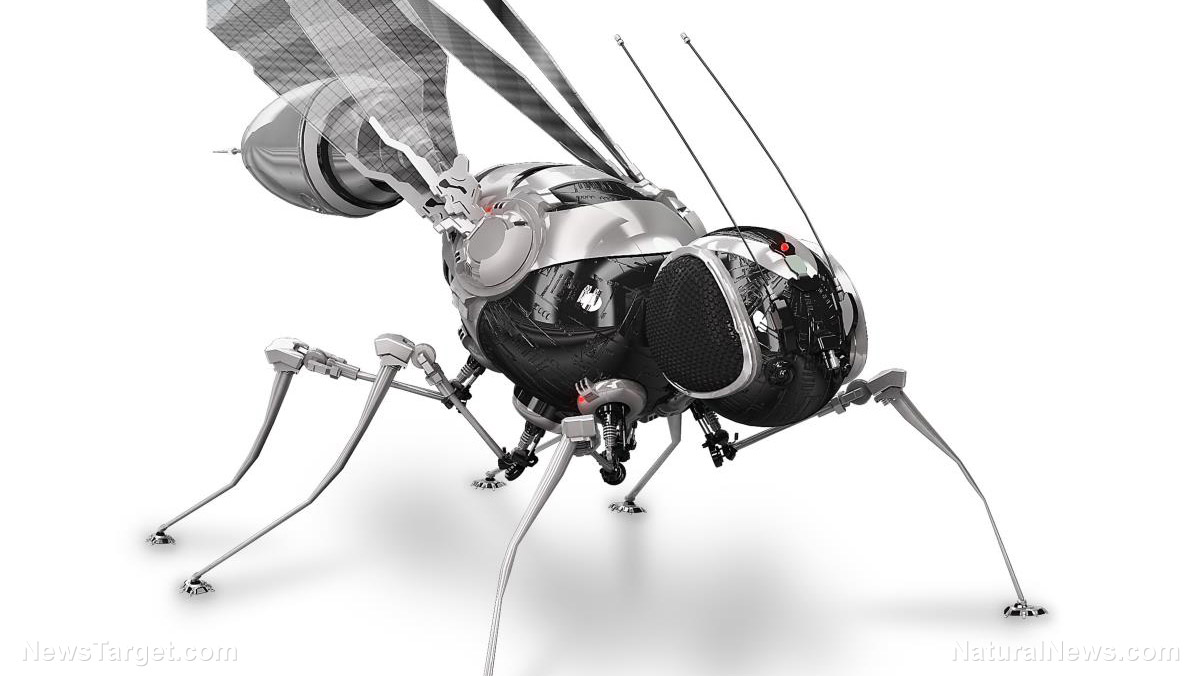

Various tech start-ups and construction companies are giving dirty, tedious, and dangerous jobs to robots. In doing so, they're transforming the face of the short-handed construction industry, according to a report from the Associated Press News.

Other sectors have already embraced automation to increase safety, speed, and productivity. Now it's the turn of the construction industry, which sees robots as a solution to its dearth of skilled workers and huge backlog of construction projects.

San Francisco-based start-up Built Robotics is automating construction vehicles like bulldozers and excavators. The machines will be able to dig and level soil at construction sites with no need for a human behind the steering wheel.

“The idea behind Built Robotics is to use automation technology make construction safer, faster and cheaper,” says the start-up's founder Noah Ready-Campbell, a former Google Engineer.

His business partner, Michael Chui of the McKinsey Global Institute, explains that the construction industry requires both robots and human workers to successfully grow the economy. Companies will need to retrain workers to fulfill new functions as robots take over their old jobs.

For example, Colorado-based Berich Masonry recently acquired a bricklaying robot called Semi-Automated Mason (SAM). The machine can lay bricks much faster than a human mason who works by hand.

The displaced workers learned how to operate their new robot. While the one-armed SAM built the brick wall of an elementary school building, Berich masons kept it fed with bricks and wiped away any excess mortar.

“There are lots of things that SAM isn’t capable of doing that you need skilled bricklayers to do,” said Brian Kennedy, who directs policy for the International Union of Bricklayers and Allied Craftworkers. (Related: Human agriculture laborers soon OBSOLETE: U.K. researchers grow the world’s first crops using nothing but drones and robots.)

Skilled manpower shortage leads to rise of the construction robots

A severe shortage in skilled labor has forced the construction industry to resort to robotic assistance. The Associated General Contractors of America reports that 70 percent of the construction firms are hurting for warm bodies.

“To get qualified people to handle a loader or a haul truck or even run a plant, they’re hard to find right now. Nobody wants to get their hands dirty anymore," laments Mike Moy, a manager at California-based Lehigh Hanson.

Previously, he hired a contractor to measure the mounds of rock and sand that his company sells. The contractor would spend an entire day driving a truck around the 90-acre mining plant in order to scan every pile with a laser.

Now Moy uses a quadcopter drone, which takes 25 minutes to overfly the area. The UAV sends the data to its maker, the start-up Kespry, which converts the data into 3D maps and sends it to customers like Lehigh Handson.

Kespry CEO George Matthew claims aerial drone surveys are safer, faster, and provide up to 100 times more data than human surveyors.

A partnership between humans and smart machines

Back in California, Ready-Campbell remembers the tough days when he worked for his father's construction company. He believes humans and smart machines are working together to reshape the construction industry.

The young CEO of Built Robotics explains that robots will take over the dangerous, monotonous, and repetitive tasks that comprise 80 percent of construction work. Meanwhile, the human devotes his experience and finesse to the remaining 20 percent.

His company refitted a bulldozer with autonomous driving technology and associated sensors. The prototype vehicle was transported to a construction site in San Jose, California, where it successfully moved mounds of earth and graded the soil without a human operator.

The demonstration not only proved the viability of a robot bulldozer, but also earned money for Built Robotics on the side.

Visit Robot.news to learn more about the applications of robotics on various industries.

Sources include:

Please contact us for more information.